COCA-COLA EQUIPMENT archives

coca-cola equipment archives

COCA-COLA EQUIPMENT

In 2006, Voron took on the challenge to build Coke’s first industrial design team and rebuild Coca-Cola’s equipment platform as an engaging and alluring brand connection for consumers. He realized shortly thereafter that he would have to not only influence how the company innovating relative to equipment design and technologies but that he would have to change the beverage vending equipment manufacturing model.

In 2007, Voron had the vision to SHIFT THE APPROACH regarding how Coca-Cola’s core packaging and equipment assets were developed, before Voron’s leadership, Coke would design what they could MANUFACTURER. In the past, innovation technologies were conceived in-house and executed by various suppliers around the world based on their local constraints. This was an effective way to quickly build scale in over 200 countries; however, this inhibited Coke from differentiating in a bold and consistent way.

By 2009, Coke had made the shift and they began manufacturing what they DESIGNED. They continued to worke closely with many of the same global partners; howewver, they shifted their approach to creating equipment based on global standards that were designed by Coke to improve the consumer experience and the effectiveness of coolers, vending and fountain equipment that dispense Coke products. There were several reasons why Voron’s team at Coke cared about this … the primary reason was the reach and impact to connect with million of consumers daily.

COCA-COLA EQUIPMENT

In 2006, Voron took on the challenge to build Coke’s first industrial design team and rebuild Coca-Cola’s equipment platform as an engaging and alluring brand connection for consumers. He realized shortly thereafter that he would have to not only influence how the company innovating relative to equipment design and technologies but that he would have to change the beverage vending equipment manufacturing model.

In 2007, Voron had the vision to SHIFT THE APPROACH regarding how Coca-Cola’s core packaging and equipment assets were developed, before Voron’s leadership, Coke would design what they could MANUFACTURER. In the past, innovation technologies were conceived in-house and executed by various suppliers around the world based on their local constraints. This was an effective way to quickly build scale in over 200 countries; however, this inhibited Coke from differentiating in a bold and consistent way.

By 2009, Coke had made the shift and they began manufacturing what they DESIGNED. They continued to worke closely with many of the same global partners; howewver, they shifted their approach to creating equipment based on global standards that were designed by Coke to improve the consumer experience and the effectiveness of coolers, vending and fountain equipment that dispense Coke products. There were several reasons why Voron’s team at Coke cared about this … the primary reason was the reach and impact to connect with million of consumers daily.

COKE’S FIRST INTERACTIVE VENDING MACHINE 2008

COCA-COLA FREESTYLE DRIVE-THRU WINDOW FOUNTAIN DISPENSER

COKE’S FIRST 3D EQUIPMENT DESIGN LANGUAGE & PLATFORM

COKE’S FIRST 3D EQUIPMENT DESIGN LANGUAGE & PLATFORM

COKE’S FIRST 3D EQUIPMENT DESIGN LANGUAGE & PLATFORM

Other Work

Ripple Got It CampaignRipple

Dolby Brand Design SystemPayID Product & Brand Design

Dolby UX/UI DesignDolby

Dolby VoiceDolby

EscapeDolby

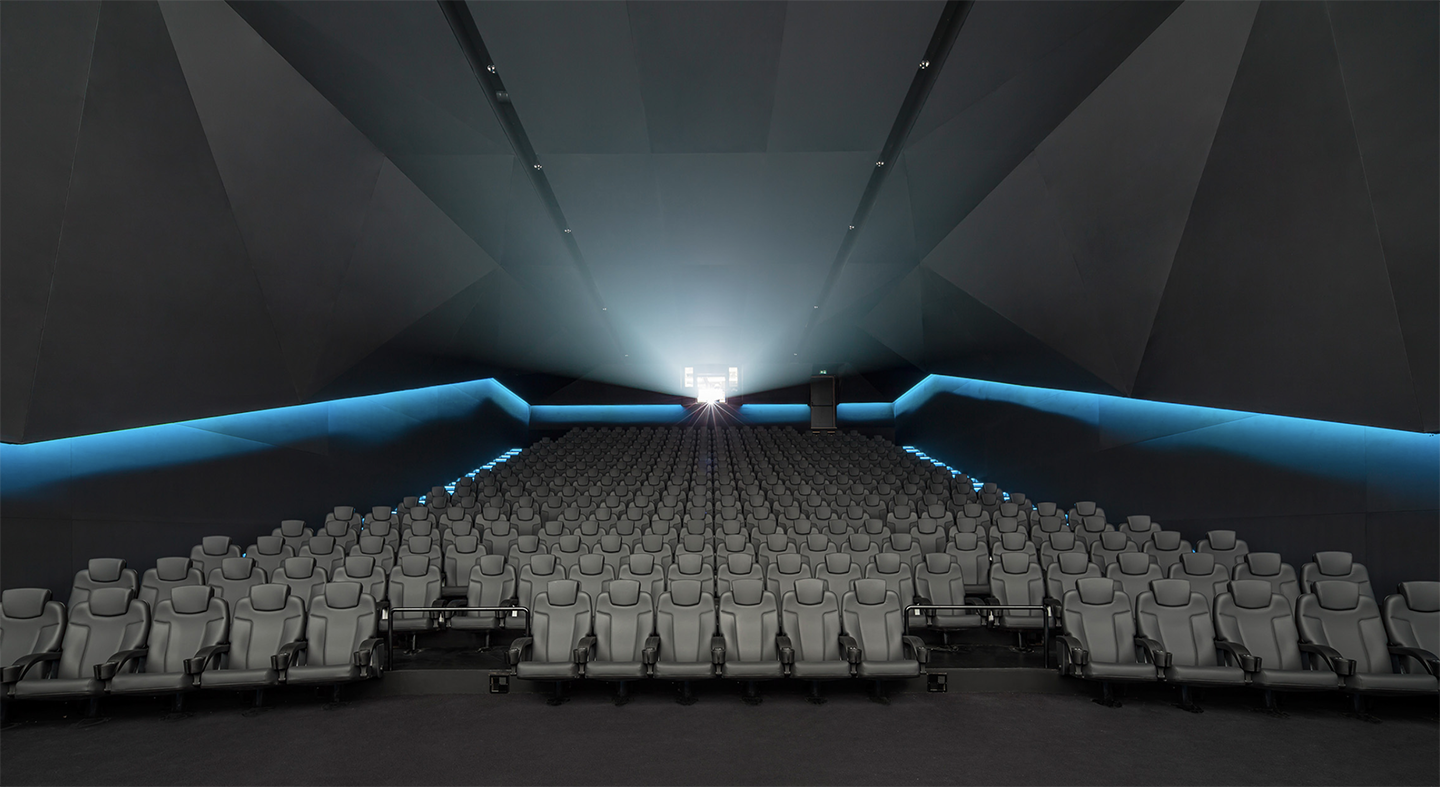

Dolby CinemaDolby

SilentDolby

Dolby SohoDolby

Dolby InstituteDolby

Dolby Art SeriesDolby

Dolby PhotographyDolby

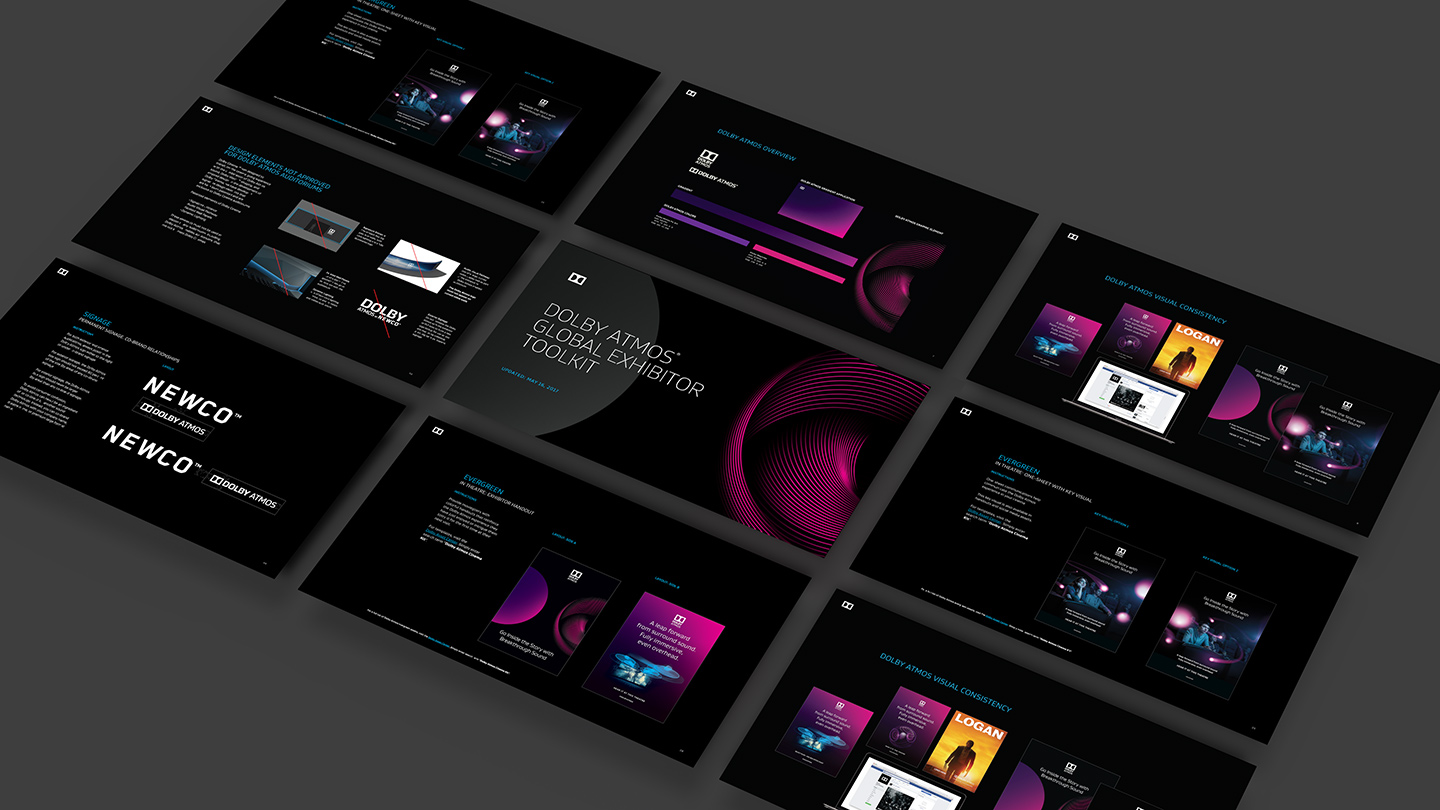

Partners ToolkitsDolby

Coca-Cola FreestyleCoca-Cola

Times Square Interactive BillboardCoca-Cola

Coke Brand Design SystemCoca-Cola

EMECO COKE 111 NAVY CHAIRCoca-Cola

Coca-Cola PackagingCoca-Cola

Coca-Cola Digital DesignCoca-Cola

Apple ArchiveApple

Apple is a registered trademark of Apple Inc, Coca-Cola is a registered trademark of The Coca-Cola Company, Dolby and the double-D symbol are registered trademarks of Dolby Laboratories.Hey there, this is the default text for a new paragraph. Feel free to edit this paragraph by clicking on the yellow edit icon. After you are done just click on the yellow checkmark button on the top right. Have Fun!